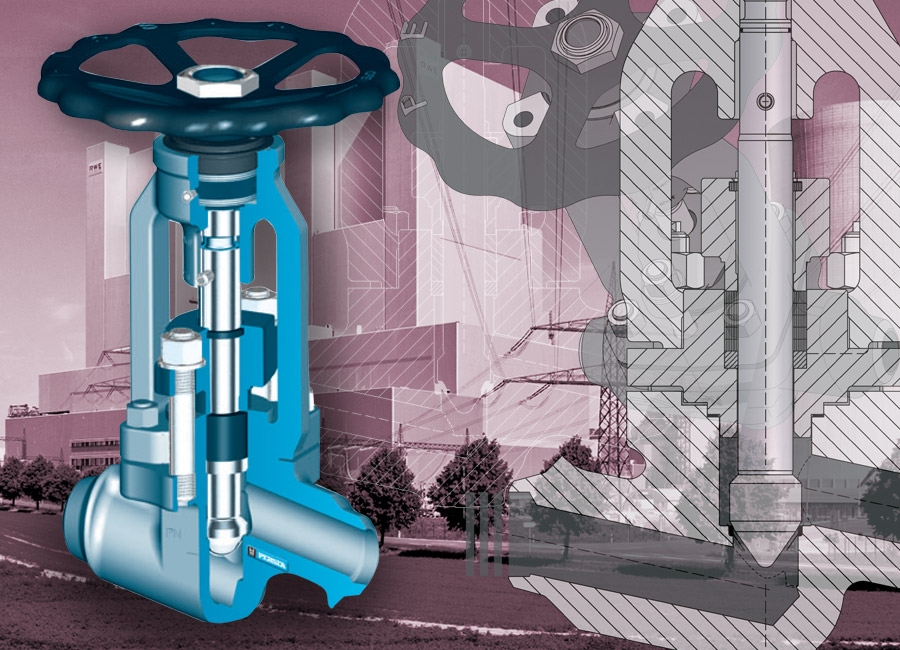

Globe Valves up to PN630

Configuration

Construction bonnet less and pressure seal bonnet.

Body materials:

- Carbon steel: 1.5415, 1.0460

- Alloy steel: 1.4901, 1.4903, 1.7335, 1.7383, 1.6368

- Stainless steel: 1.4571

- Other materials on request

- DN 10-65, PN up to 630, DN 65-250, PN up to 500

Connections:

- Flanges

- Butt weld ends

- Socket weld ends

- Other connections

Features

- Disc and stem in one piece

- Die-forged valve body and bonnet

- Non-turning, rising stem

- Position indicator / anti-rotation device

- Throttle disc

- > DN20 with an integral actuator flange

- HD2000 valves also available in angle pattern

Design Highlights

- Body seat: tapered seat welded on integratedly with stellite

No pressed in or screwed seat ring, therefore no crevice corrosion or loosening - Disc and stem in one piece; up from +570°C with stellited tapered seat

Damage between disc and stem due to high flowrates is prevented - Sealing to the outside only by means of the gland packing

No bonnet gasket, therefore reduction of possible leakage areas - Body and bonnet in two separate pieces with bolted bonnet

To ease maintenance work, e.g. regrinding of the body seats - Yoke sleeve made of bronze

Good emergency running properties - Cup springs above the upper needle bearing

To maintain the necessary closing forces when dimensions change between stem and yoke arm due to thermal fluctuation

Manufacturer

PERSTA is a market leader in the high performance forged steel isolating valves. Established manufacturer, part of the Siepmann Group with their own forging shop. Especially the high pressure globe and gate valves are a benchmark in the valve industry with a flexible production process.

- Globe valves

- Gate valves

- Check valves

- Bellow seal valves

- Special valves

- Valves for super critical boilers