Stop Check Valves Featured

In many applications the use of a combination of a stop valve and a check valve is used. This results in two pressure containing parts, two potential leak paths and the added issues of space requirements, more weight, the extra insulation needed and the additional cost factor.

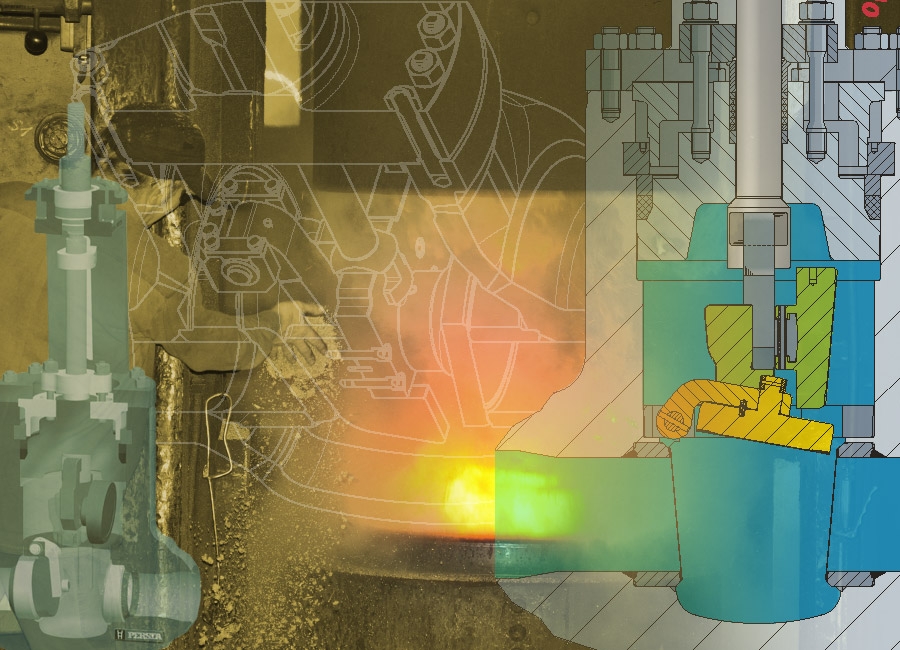

New developments within PERSTA have combined the tapered parallel slide gate valve, with a full swing check valve, brought together in one valve body. Based on a standard gate valve body and standard stock items a stop-check valve can be created. With a swing check valve and the straight through pattern of the valve body the pressure drop is negligible. When the valve is required to be closed an additional disk is lowered on a second downstream seat. The mounting arrangement of the second disk is provides a positive closing force on the swing check disk resulting in a tight bidirectional closure. Now the stop-check valve is performing as a tapered parallel slide gate valve.

Advantages

- Needs less space

- Needs less insulation

- Lower total weight

- Lower maintenance costs

Materials

- ASTM A 182 F12

- ASTM A 182 F 22

- ASTM A 182 F 91

Manufacturer

PERSTA is a market leader in the high performance, forged steel isolating valves. An established manufacturer, part of the Siepmann Group with their own forging shop. Especially the high pressure globe and gate valves are a benchmark in the valve industry with a flexible production process.

- Globe valves

- Gate valves

- Check valves

- Bellow seal valves

- Special valves

- Valves for super critical boilers