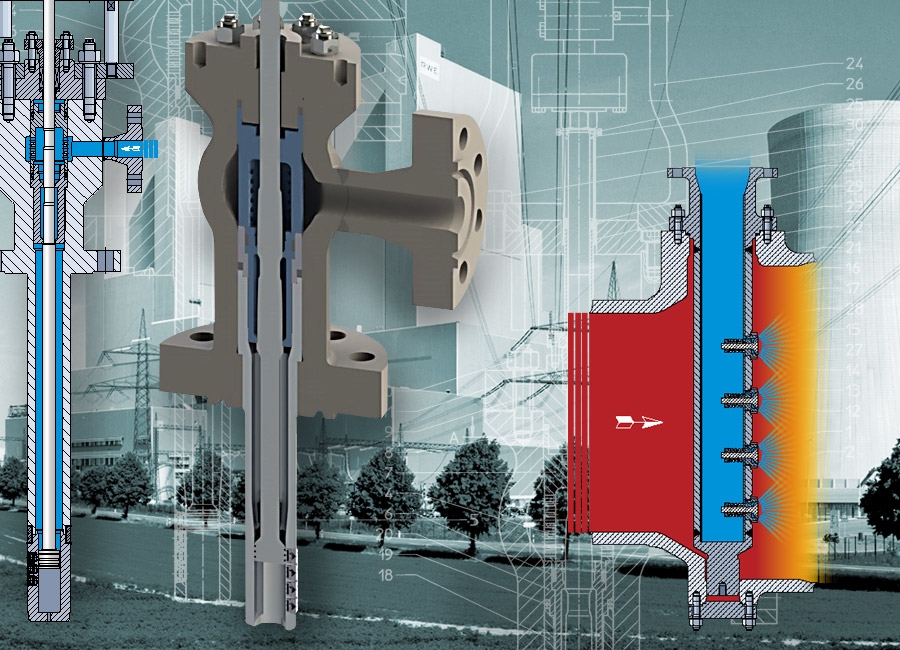

Steam Cooling

Steam cooling is the opposite process of super heating and crucial in several processes. HORA manufactures a complete package of different types of desuperheaters, every type with its particular properties. HORA precisely determine the CFD (Computer Fluid Dynamics) analysis for your application providing the optimum, most cost-effective version. Various products are available are available for this purpose.

Configuration

Applicable for:

- Processsteam

- Intermittent cooling superheater

- Final cooling superheater

- Condensor protection

- Other cooling applications

Configurations:

- Multi stage desuperheater

- Venturi desuperheater

- Desuperheating with atomizing unit

- Static injection lance

- "Cooled desuperheater"

Features

- One piece, forged body (F1, F11, F22 and P91)

- Integrated injection valve

- Single- of multistage internal

- Cavitation free internal

- Due to control unit, avoid cavitation and always maintain an optimum pressure drop over the nozzle

Benefits

- Easy maintenance due to clamped internals

- No separate injection valve necessary

- Anti cavitation trim

- Seat located outside hot area

- No welding connections

- Optimal spray due to optimal pressure drop over injection nozzle

- Thermoshock free!

Manufacturer

HORA is a German manufacturer of high pressure steam and water control valves covering all control systems in modern power plants. Together with a very good R&D department we are continuously seeking for better solutions and controllability of the steam water cycle. Flexible and dedicated performance company, supplying all tailor-made products.

- Control valves

- Steam conditioning valves

- Feed water Control valves

- Water injection valves

- Desuperheater valves

- Turbine bypass valves

- Turbine shut-off valves

- Automatic recirculation valves (Pump protection)

- Valves for super critical boilers