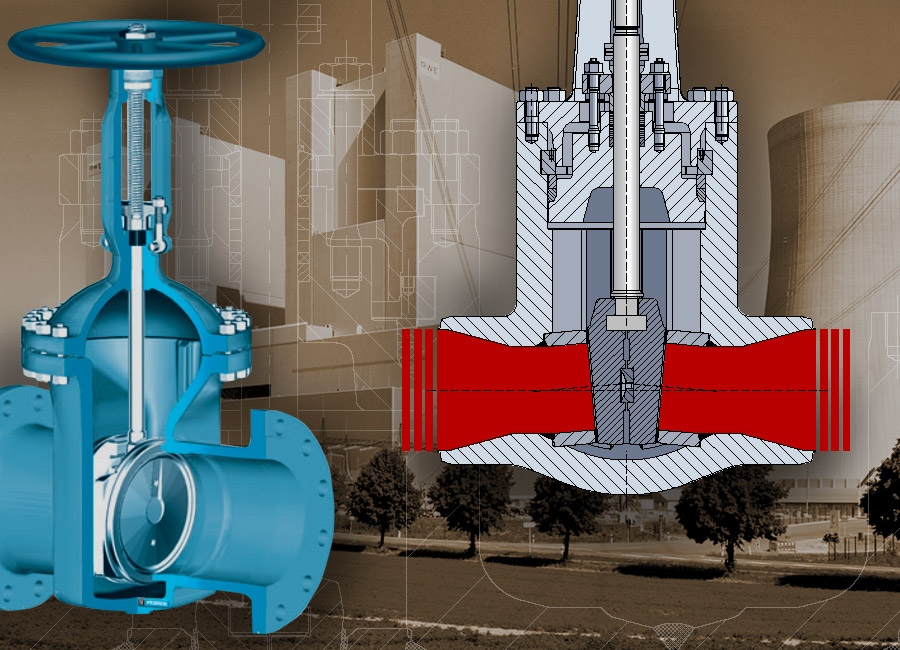

Gate Valves

Configuration

Valves with stuffing box or bellows sealed pressure seal bonnet or blank flange.

- DN 50-1000

- PN up to 40, DN 50-300

- PN up to 100, DN 50-300

- PN 160, DN 50-700

- PN 100-630 (PD 10-63), DN 10-50

- PN up to 100 (Class 800)

Body materials:

- Carbon steel: 1.0425, 1.0460, 1.5415

- Alloy steel: 1.4901, 1.4903, 1.6368, 1.7335, 1.7383,

- Stainless steel: 1.4571

- Stainless steel low temperature: 1.4308

- Other materials on request

Connections:

- Flanges

- Butt weld ends

- Socket weld ends ≤ DN 50

- ASME on request

Features

- "Split wedge" construction

- Rail guided discs

- Die-forged body and bonnet

- Non-turning, rising stem

- Spindelnut with bearing

- Easy assembly of an E-actuator

- Pressure sealed bonnet acc. VGB-guidelines

Design Highlights

- Main valve body is one-piece die-forged incorporating the bonnet flange and the guide for the shut-off device

Die-forged parts, compared with cast steel parts are generally free from porosity and shrink holes. The special of the valve body minimizes the existance of welding seams. - Valve body equipped with guiding system

Compared to parallel slide valve an almost friction free stroke - Hard faced seats (app. 35-37 HRC)

Extremely resistant to wear - Full bore, except DN 65/50 and DN 125/100

No reduction in seat area - Hammer head connection between wedge and stem

The wedges are able to move parallel to the axis of the pipeline within the guiding groove. This protects the stem against bending moments - Pressure sealing bonnet

Best possible sealing function

Manufacturer

PERSTA is a market leader in the high performance forged steel isolating valves. Established manufacturer, part of the Siepmann Group with their own forging shop. Especially the high pressure globe and gate valves are a benchmark in the valve industry with a flexible production process.

- Globe valves

- Gate valves

- Check valves

- Bellow seal valves

- Special valves

- Valves for super critical boilers