Maximize your operational flexibility with AVS/Hora attemperators

23 April, 2024Final and intermediate attemperators in powerplant with start stop operation.

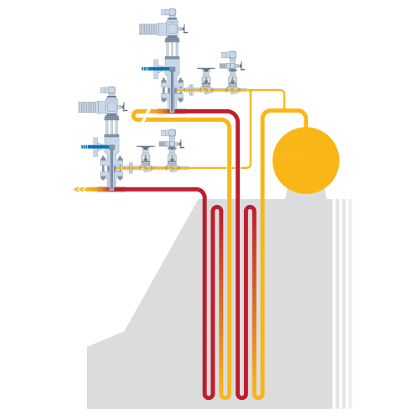

Attemperators play a crucial role in gas-fired power plants to meet the demands of changing operating conditions and ensure reliable and flexible power generation. With our cutting-edge technology and top-notch engineering, our Attemperators boast a lifetime expectancy of over 25 years or more than 250,000 cycles! These improvements contribute to a more responsive and environmentally friendly power supply that complements renewable energy sources on the grid.

Design features AVS/Hora attemperators:

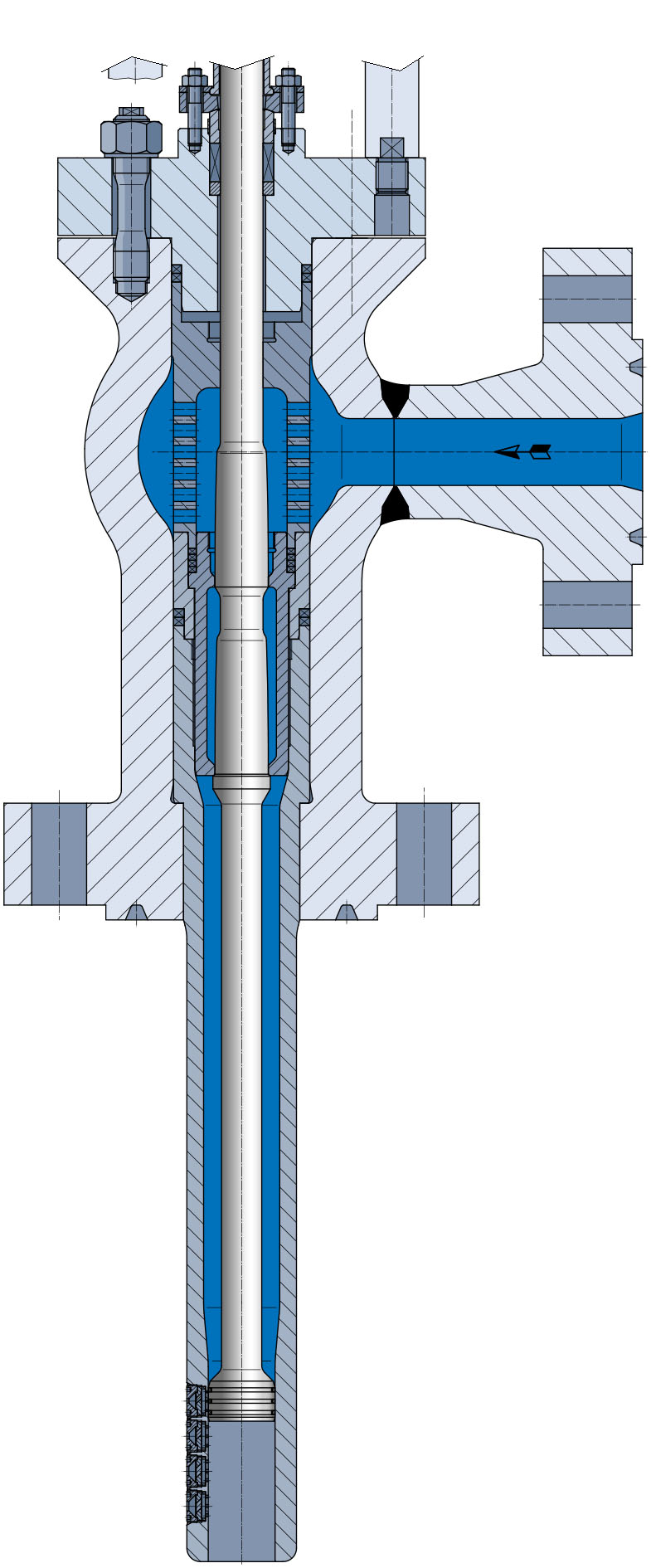

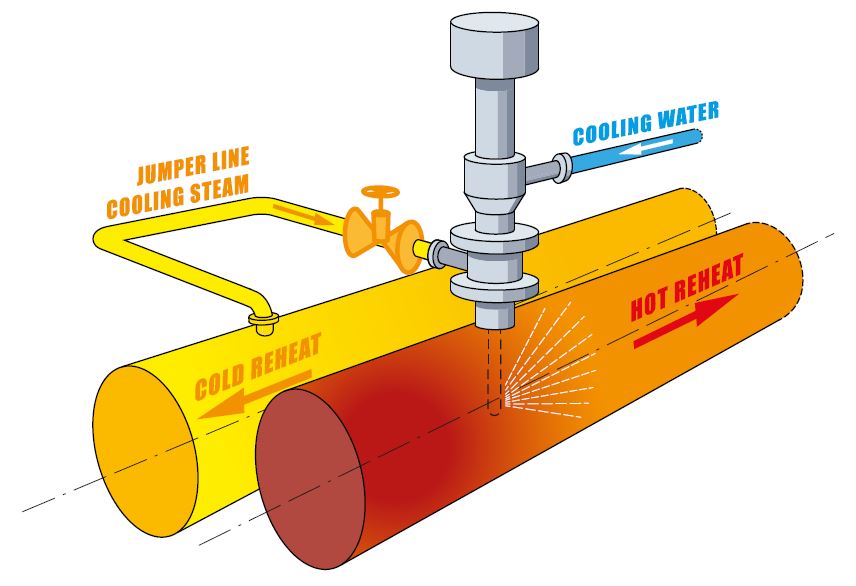

Small Water Droplets: Attemperators need to produce small water droplets over the full operating range to ensure quick evaporation. Pressure drop at the point of injection is used to create small water droplets. The use of a spray nozzle head with multiple swirl nozzles, opened one by one by a piston, helps achieve fine cooling with a constant pressure drop over each nozzle, even at the first start at the beginning.

Multi-Nozzle Attemperators: Multi-nozzle attemperators are favoured over single nozzle coolers and multi nozzle ring type coolers as they offer better performance (small droplets) over the full rangeability.

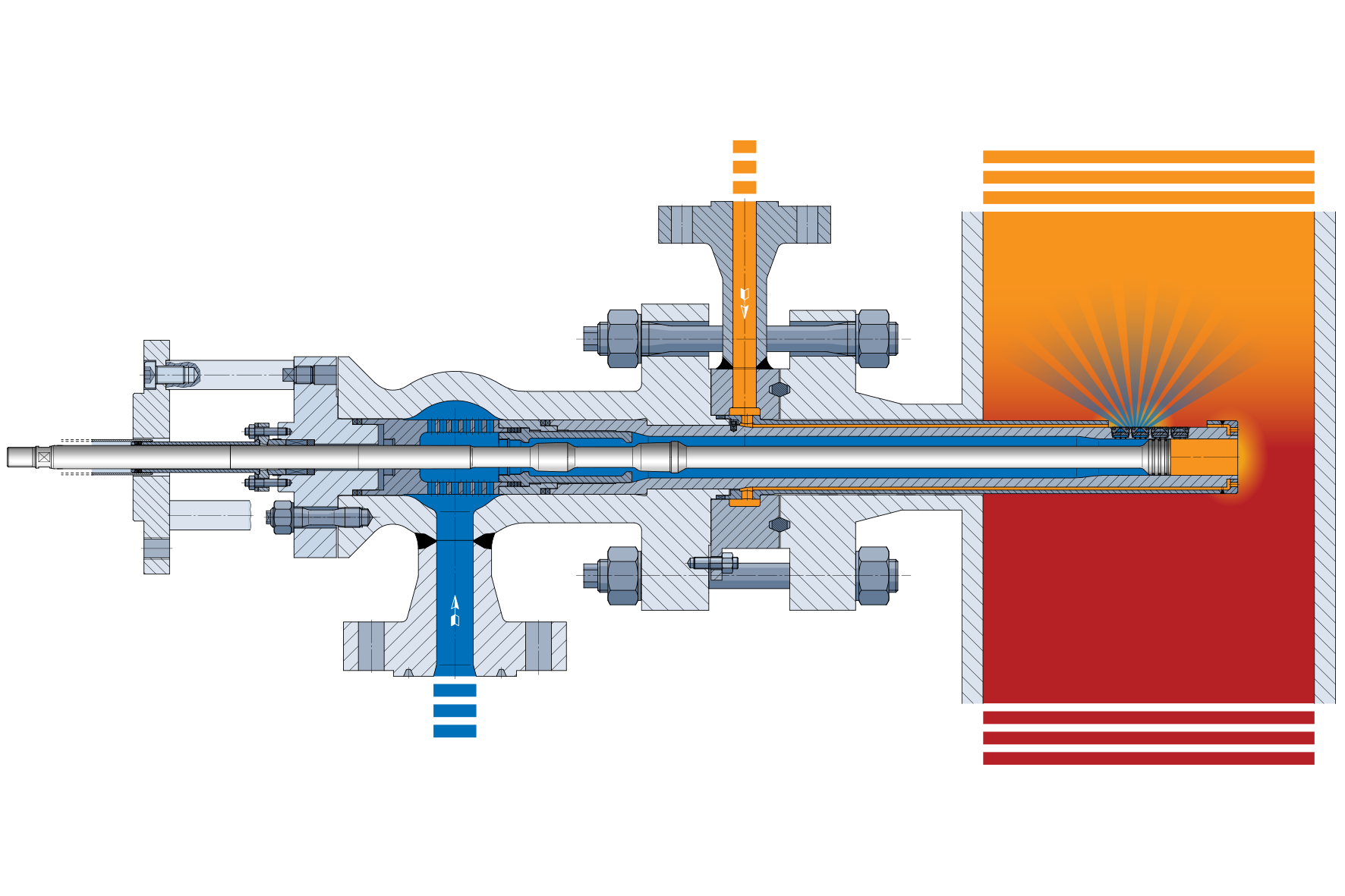

Injection mast: Is designed and made from one piece which provides better resistant to thermal stress. Easy to maintain as it can be retracted keeping the valve body installed.

Integrated control valve: To have perfect control with multiple pressure stages, so no need for separate control valve.

High Cycle Attemperators: In certain situations, attemperators experience thermal stress during start-up, shut down, or emergencies. High cycle attemperators are designed with a mast with integrated nozzle head, providing better durability and a much longer service life.

The cooled high cycle attemperator: Additionally, the mast of the attemperator is cooled with a small amount of saturated steam. This helps in reducing the temperature difference between the cooling water and the mast/steam temperature. As a result, the attemperator becomes suitable for frequent starts and stops without causing any thermal shocks or sudden temperature changes that could be detrimental to the equipment.

- Achievable Lifetime Expectancy: With the implementation of cooled high cycle attemperators and cooling with saturated steam, a lifetime expectancy of more than 25 years or over 250,000 cycles is anticipated.

Powerplant efficiency increase: the use of this type of attemperator can lead to an increase in the power output of the plant (MW), compared to other attemperators that require continuous spraying of cooling water. Traditional attemperators often need continuous cooling to protect the equipment, even when such intensive cooling is not necessary. By using saturated steam and applying cooling only when needed, the efficiency and output of the plant can be improved.