Configuration

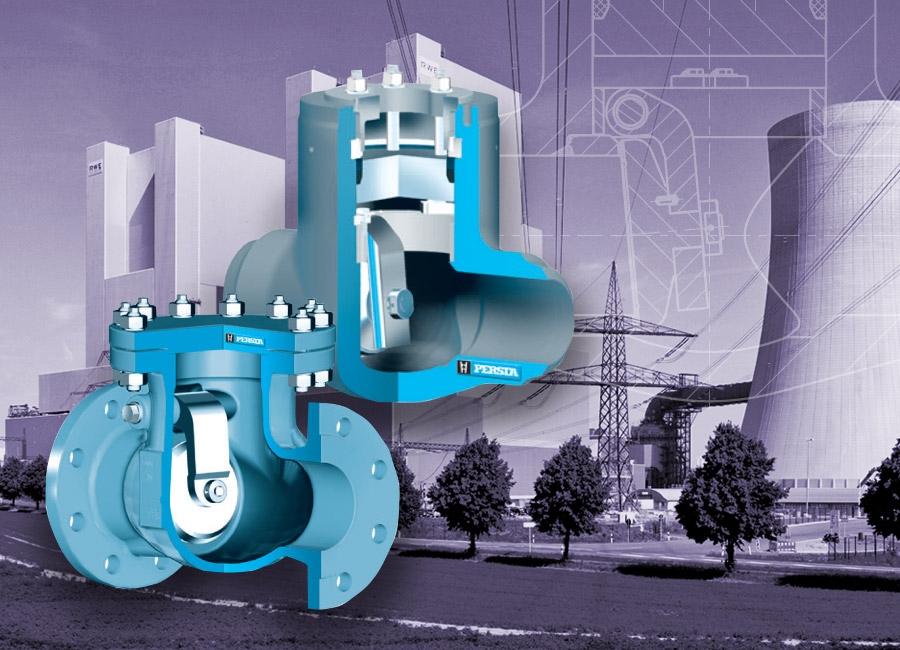

Piston type:

- Check valve, optional with screw down function

- DN 10-200, PN up to 500

Swing type:

Construction with realized or inside shaft plus pressure sealing bonnet or blank flange.

- DN 50-800, PN up to 40

- DN 50-250, PN 63-160

- DN 50-600, PN 210-630 (PD 21-63)

Materials

- Carbon steel: 1.0460, 1.0619, 1.5415, 1.5419

- Alloy steel: 1.4901, 1.4903, 1.7335, 1.7357, 1.7383

- Cold resisting steel: 1.0566, 1.7219,

- Stainless steel: 1.4571, 1.4581

- Stainless steel low temperature: 1.4308, 1.4571

Connections

- Flanges

- Butt weld ends

- Socket weld ends

- Other connections

Features

- Valve body made of forged steel

- Check valve, optional with screw down function

- Swing check valve with an internal hinge pin

- Lever rests in a separate support ring

- Available with damper

Design highlights

- Valve body forged

Free from porosity and shrink holes - Seats faced with stellite

Extremely resistant to wear - Lever rests in a separate support ring

The setting of the disc can be examined before installing the bonnet cover - Pressure sealed bonnet

Best possible sealing function

Manufacturer

PERSTA is a market leader in the high performance, forged steel isolating valves. Established manufacturer, part of the Siepmann Group with their own forging shop. Especially the high pressure globe and gate valves are a benchmark in the valve industry with a flexible production process.

- Globe valves

- Gate valves

- Check valves

- Bellow seal valves

- Special valves

- Valves for super critical boilers