Two shift operation power plants

Power stations that were originally designed for base load applications are now increasingly

being asked to operate on a two shift, stop start regime; this is more commonly known in the

industry as dual shifting. The multiple start/stops that these stations are now experiencing is in

some instances causing an increase of operational issues due to the to the constantly changing

process parameters. For example dual shift stations will experience additional thermal stress in

the headers, drums, high temperature piping, valves plus the auxiliary equipment leading to

additional wear and tear of their systems and component parts. This is due to the more frequent

use of the plant at severe service conditions. The consequences of the change in plant operation

cannot be ignored. If the plant is not operated correctly or more importantly modified properly to

handle these changes the lifetime of the components within the plant will...

(download the paper below)

Marcel

Suspendisse semper diam eget molestie convallis. Aliquam mollis, erat eu pulvinar faucibus, nisl massa lacinia ante, a bibendum nunc sapien sed dui. Suspendisse semper diam eget molestie convallis. Aliquam mollis, erat eu pulvinar faucibus, nisl massa lacinia ante, a bibendum nunc sapien sed dui.

Two shift operation power plants

Power stations that were originally designed for base load applications are now increasingly

being asked to operate on a two shift, stop start regime; this is more commonly known in the

industry as dual shifting. The multiple start/stops that these stations are now experiencing is in

some instances causing an increase of operational issues due to the to the constantly changing

process parameters. For example dual shift stations will experience additional thermal stress in

the headers, drums, high temperature piping, valves plus the auxiliary equipment leading to

additional wear and tear of their systems and component parts. This is due to the more frequent

use of the plant at severe service conditions. The consequences of the change in plant operation

cannot be ignored. If the plant is not operated correctly or more importantly modified properly to

handle these changes the lifetime of the components within the plant will decrease enormously.

The changing operational requirements of the plant require that the steam coolers, desuperheater

valves, drains, feed water control valves, main steam isolation valves and the turbine

quick closing valves are reviewed. These critical pieces of equipment...

(download the paper below)

In many applications the use of a combination of a stop valve and a check valve is used. This results in two pressure containing parts, two potential leak paths and the added issues of space and especially weight.

Based on globe valves, stop-check valves have been developed in the past. By mounting a loose disk on the spindle, the disk can function as a check valve. The main disadvantage is that these valves in most cases have not been designed as stop check valves. A second disadvantage is the fact that the pressure drop over this type of valves is high, due to...

(download the full paper below and our flyer about how Pulrose CCGT Station saved £1m installing a replacement stop check valve)

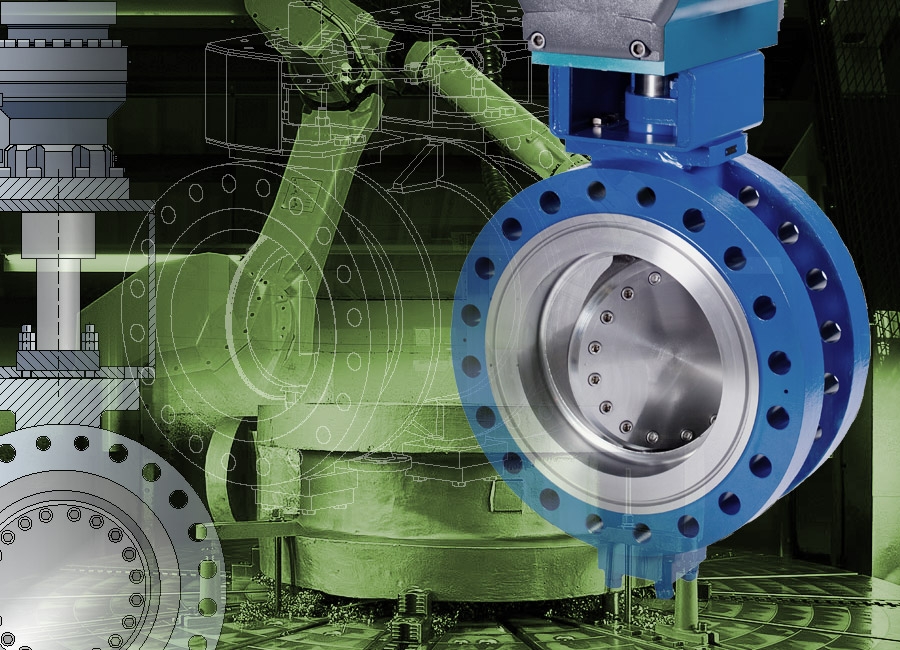

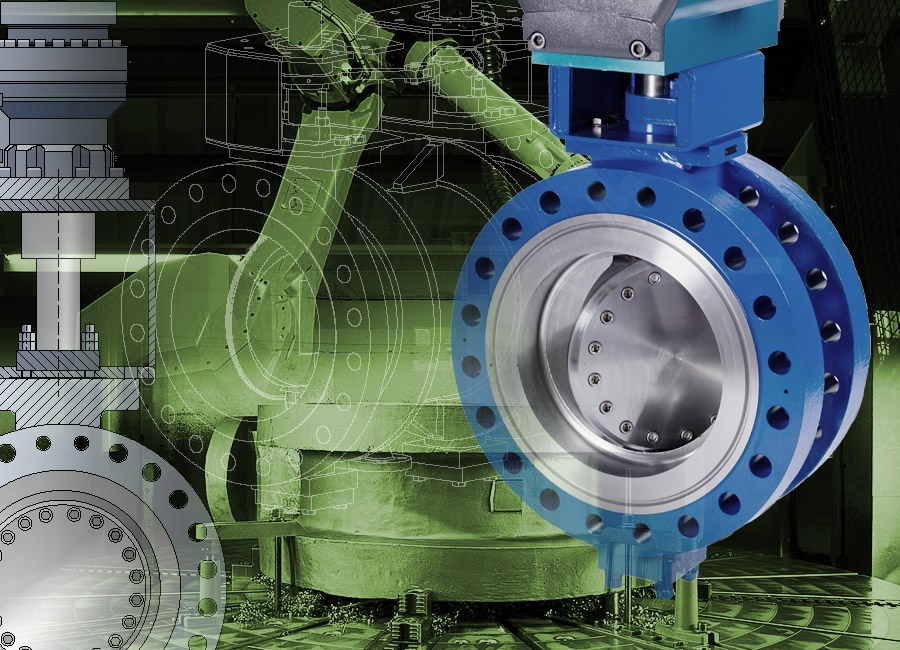

ZWICK's self-centrering disc design that is keyed to the shaft accommodates differential thermal expansions of the disc and the shaft. The triple offset geometry assures friction free running without radial loading of the seal ring and break-away torque. The TRI-CON series reaches a superior unrivaled life time cycle. For critical services a patented sealed bearing solution is offered to prevent fouling of the bearing associated with line media.

Configurations

- TRI-CON

- TRI-CHECK

- TRI-BLOCK

Standard Features

- Triple eccentric design

- Metal seating

- Pressure classes according ANSI 150/300/600/900 and PN 10/16/25/40/63/100/160

- Full bi-directional shutoff as per API 598 and/or DIN EN 12266-1

- Temperature range up to 815°C

- Size range 2" - 88" (DN 50-2200)

- Friction free opening and closing

- Vacuum tight

- Laminated seal and seat made of stainless steel

- Anti blow-out shaft API 609

- Steel casting, stainless steel, special alloys

- Fire-safe acc. to BS 6755 and API 607 4th ed. for both flow directions

- Fugitive emission control acc. to "TA-Luft II"

- Optional Double Block & Bleed Design

- Special customer requirements on request

- SIL 3

- EPA 21

Benefits

Self-centering disc

The construction guarantees the optimal position of the laminated seal against the seat. Jamming due to thermal expansion is eliminated.

Torque transmission using keys

The disc is keyed to the shaft not pinned, providing balanced torque transmission and eliminating the danger of pins shearing off.

Ideal lamination and disc design

The strong disc with its eliptical supporting surface offers the best fixing of the lamination. Bubble tightness is given as a result of the special machining of the lamination.

Supporting bearing bushings

The optimal position of the bearing reduces the risk of the shaft bending. This guarantees bi-directional tightness at maximum differental pressure.

Applications

- Oil and gas

- Chemical

- Petrochemical

- Energy

- Offshore

- Steel

Manufacturer

ZWICK is a German manufacturer of high performance triple offset butterfly valves. ZWICK is excellent in short delivery times because of a flexible and effective organisation. ZWICK successfully passed the Shell TAMAP procedure and achieved the very low allowable Fugitive Emission leakage rates.

- Metal seated (SS/graphite & solid metal) Butterfly valves (wafer/lug type, double flanged, welded ends)

- Patented inclusion free bearings

- (Quick closing) Check valves

- Double Block & Bleed valves

ZWICK's self-centrering disc design that is keyed to the shaft accommodates differential thermal expansions of the disc and the shaft. The triple offset geometry assures friction free running without radial loading of the seal ring and break-away torque. The TRI-CON series reaches a superior unrivaled life time cycle. For critical services a patented sealed bearing solution is offered to prevent fouling of the bearing associated with line media.

Configurations

- TRI-CON

- TRI-CHECK

- TRI-BLOCK

Standard Features

- Triple eccentric design

- Metal seating

- Pressure classes according ANSI 150/300/600/900 and PN 10/16/25/40/63/100/160

- Full bi-directional shutoff as per API 598 and/or DIN EN 12266-1

- Temperature range up to 815°C

- Size range 2" - 88" (DN 50-2200)

- Friction free opening and closing

- Vacuum tight

- Laminated seal and seat made of stainless steel

- Anti blow-out shaft API 609

- Steel casting, stainless steel, special alloys

- Fire-safe acc. to BS 6755 and API 607 4th ed. for both flow directions

- Fugitive emission control acc. to "TA-Luft II"

- Optional Double Block & Bleed Design

- Special customer requirements on request

- SIL 3

- EPA 21

Benefits

Self-centering disc

The construction guarantees the optimal position of the laminated seal against the seat. Jamming due to thermal expansion is eliminated.

Torque transmission using keys

The disc is keyed to the shaft not pinned, providing balanced torque transmission and eliminating the danger of pins shearing off.

Ideal lamination and disc design

The strong disc with its eliptical supporting surface offers the best fixing of the lamination. Bubble tightness is given as a result of the special machining of the lamination.

Supporting bearing bushings

The optimal position of the bearing reduces the risk of the shaft bending. This guarantees bi-directional tightness at maximum differental pressure.

Applications

- Oil and gas

- Chemical

- Petrochemical

- Energy

- Offshore

- Steel

Manufacturer

ZWICK is a German manufacturer of high performance triple offset butterfly valves. ZWICK is excellent in short delivery times because of a flexible and effective organisation. ZWICK successfully passed the Shell TAMAP procedure and achieved the very low allowable Fugitive Emission leakage rates.

- Metal seated (SS/graphite & solid metal) Butterfly valves (wafer/lug type, double flanged, welded ends)

- Patented inclusion free bearings

- (Quick closing) Check valves

- Double Block & Bleed valves

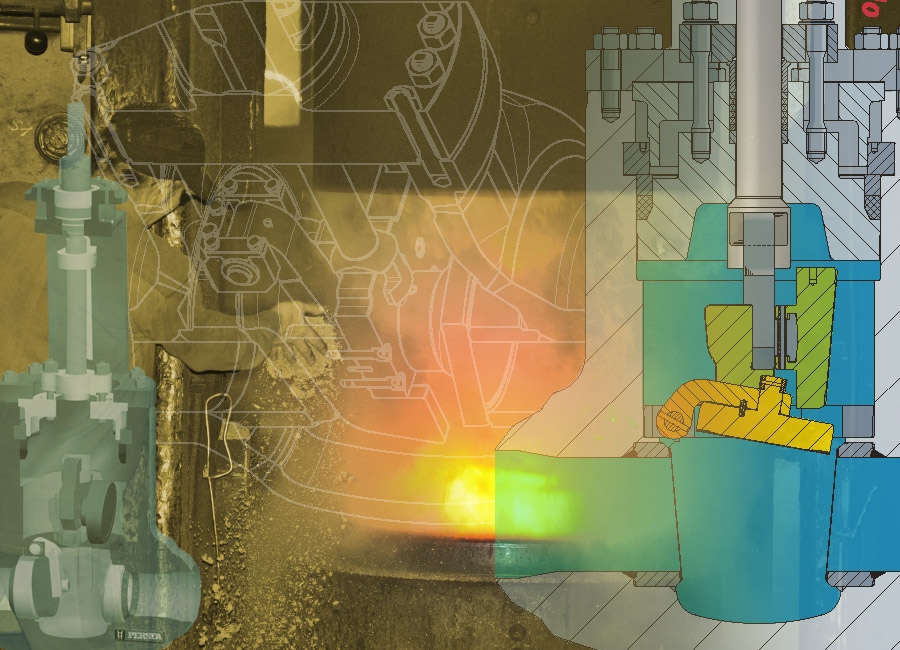

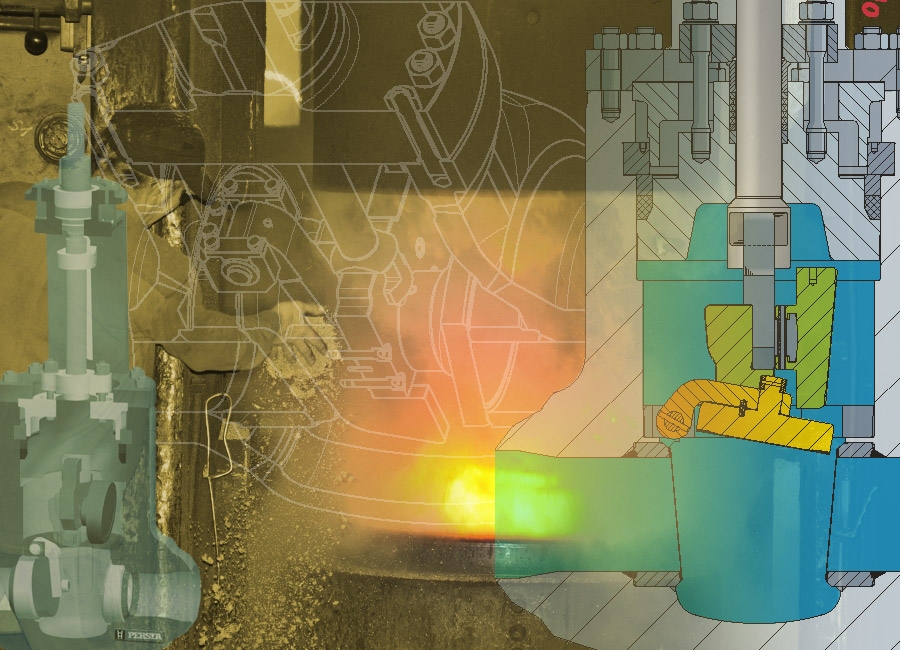

In many applications the use of a combination of a stop valve and a check valve is used. This results in two pressure containing parts, two potential leak paths and the added issues of space requirements, more weight, the extra insulation needed and the additional cost factor.

New developments within PERSTA have combined the tapered parallel slide gate valve, with a full swing check valve, brought together in one valve body. Based on a standard gate valve body and standard stock items a stop-check valve can be created. With a swing check valve and the straight through pattern of the valve body the pressure drop is negligible. When the valve is required to be closed an additional disk is lowered on a second downstream seat. The mounting arrangement of the second disk is provides a positive closing force on the swing check disk resulting in a tight bidirectional closure. Now the stop-check valve is performing as a tapered parallel slide gate valve.

Advantages

- Needs less space

- Needs less insulation

- Lower total weight

- Lower maintenance costs

Materials

- ASTM A 182 F12

- ASTM A 182 F 22

- ASTM A 182 F 91

Manufacturer

PERSTA is a market leader in the high performance, forged steel isolating valves. An established manufacturer, part of the Siepmann Group with their own forging shop. Especially the high pressure globe and gate valves are a benchmark in the valve industry with a flexible production process.

- Globe valves

- Gate valves

- Check valves

- Bellow seal valves

- Special valves

- Valves for super critical boilers

The use of a Y-type globe stop check valve is well known to replace a separate stop and check valve. However our new PERSTA DRA stop check valve will be the new standard as this type combines the advantages of a combined configuration with a much lower pressure drop and a non-sticking trim. In main steam line applications, the DRA stop check valve will even contribute to an increase in revenue.

Advantages

- Unmatched low pressure drop

- Unmatched low maintenance cost

- Needs less space than two separate valves

- Needs less insulation than two separate valves

- Lower total weight than two separate valves

Materials

- ASTM A 182 F12

- ASTM A 182 F 22

- ASTM A 182 F 91

Download/open: Report on how Persta Stop Check Valve Protects Pulrose Power Station From £1m Repair.

Read our white paper on Stop Check Valves

Manufacturer

PERSTA is a market leader in the high performance, forged steel isolating valves. An established manufacturer, part of the Siepmann Group with their own forging shop. Especially the high pressure globe and gate valves are a benchmark in the valve industry with a flexible production process.

- Globe valves

- Gate valves

- Check valves

- Bellow seal valves

- Special valves

- Valves for super critical boilers

There are applications for steam coolers in very complex situations. One common example is if a cooler is not working continuously and only has to function occasionally. This can occur for example during start up and shut down or in case of an emergency to protect the main steam lines. In this instance the nozzle section will become very hot. The moment the cooler is required to start, thermal shock will occur and the cooler will be permanently damaged. In practice a very limited number of cycles can be expected before the cooler is damaged.

Solution

After years of investigation, Advanced Valve Solutions and HORA developed a solution for this particular problem, the “cooled desuperheater”. To avoid thermal stress in the cooler valvebody, the temperature differential between the cooling water and the superheated steam temperature should be significantly reduced. A temperature reduction of the valvebody to the saturated steam temperature, instead of superheated, will bring the temperature differential down to figures which will not lead to thermal shock. The cooler is now suitable for numerous starts and stops.

Life expectancy of > 25 years. Number of possible cycles > 100.000

A limited amount of saturated steam is bypassing the superheater and is brought into a “cooling jacket”. This saturated steam is cooling the valvebody, keeping it on saturated temperature. The saturated steam leaves the jacket and will mix up with the super heated steam. The saturated steam flow to the cooler is controlled by a small control valve and a manual stop check valve.

The following paper highlights the use of cooled desuperheaters in Marchwood CCGT Power Station saving £200,000 per year.

Download/open: Report on how Marchwood CCGT Power Station saved £200,000 per year by replacing desuperheater valves. (document opens in your browser PDF viewer if you have one, or otherwise use right-click and save link on your hard disk)

Read our white paper on Two shift cooled desuperheaters

Manufacturer

HORA is a German manufacturer of high pressure steam and water control valves covering all control systems in modern power plants. Together with a very good R&D department we are continuously seeking for better solutions and controllability of the steam water cycle. Flexible and dedicated performance company, supplying all tailor-made products.

- Control valves

- Steam conditioning valves

- Feed water Control valves

- Water injection valves

- Desuperheater valves

- Turbine bypass valves

- Turbine shut-off valves

- Automatic recirculation valves (Pump protection)

- Valves for super critical boilers

Perrin GmbH manufactures ball valves for use in nearly every professional environment and for customers all over the world. This well respected German manufacturer, supplies mainly special type of ball valves for Petrochemical, Chemical, Oil & Gas, Power Plants, Cement, Steel mills and liquid gases (e.g. LNG) applications.

Standard Features

Temperature range:

-196 °C to + 800 °C

-320 °F to + 1470 °F

Size range:

DN 1/2" to DN 24"

Medium:

Fluids, Gas, Solids (inc. corrosive/abrasive mediums)

Pressure range:

ANSI Class 150 to

Class 2500

Materials

- Carbon steel

- Stainless steel

- Titanium

- Hastelloy

- Duplex

- Inconel & Monel

- Special materials

Perrin GmbH manufactures ball valves for use in nearly every professional environment and for customers all over the world. This well respected German manufacturer, supplies mainly special type of ball valves for Petrochemical, Chemical, Oil & Gas, Power Plants, Cement, Steel mills and liquid gases (e.g. LNG) applications.

Standard features

Temperature range:

-196 °C to + 800 °C

-320 °F to + 1470 °F

Size range:

DN 1/2" to DN 24"

Medium:

Fluids, Gas, Solids (inc. corrosive/abrasive mediums)

Pressure range:

ANSI Class 150 to

Class 2500

Materials

- Carbon steel

- Stainless steel

- Titanium

- Hastelloy

- Duplex

- Inconel & Monel

- Special materials