Nil-Cor is the worlds largest supplier of High Technology industrial valves made from strong, light weight composite materials. The graphite and fiberglass reinforced thermoset and thermoplastic resins are resistant to acids, caustics, bleaches and more than one thousand other industrial and waste treatment chemicals, at half the cost of traditional alloy valves.

Configuration

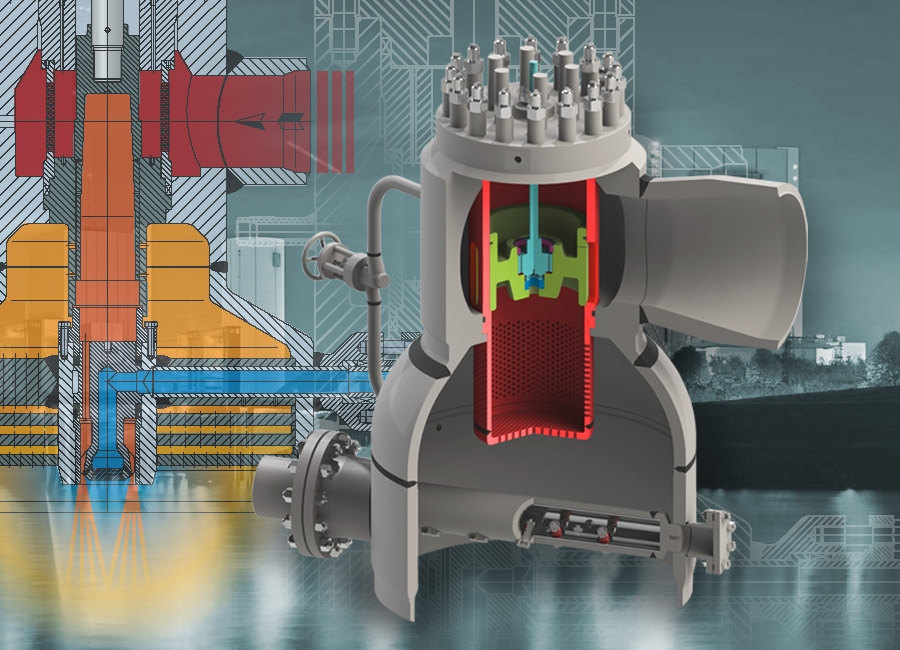

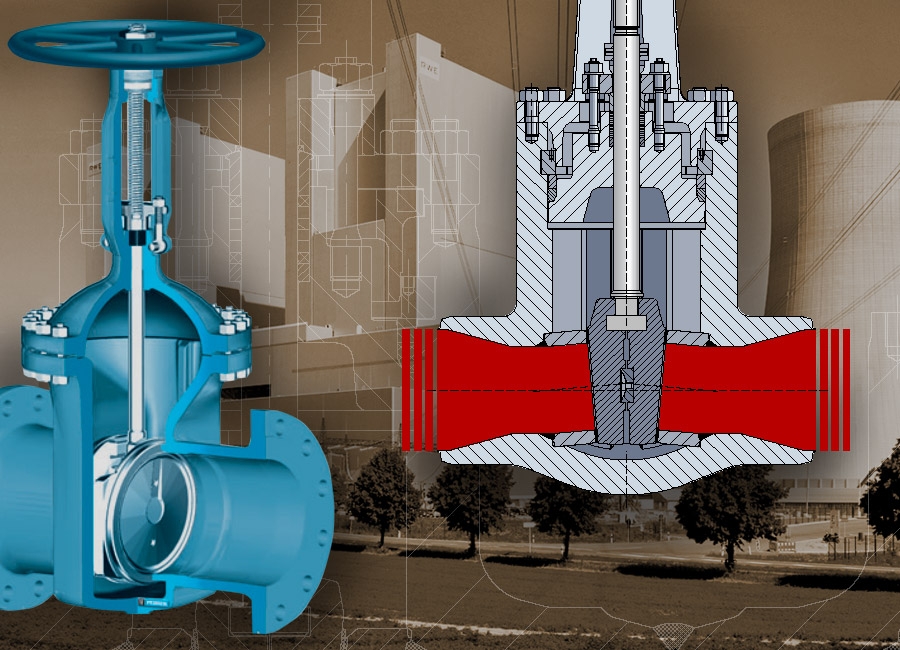

Zirconia ceramic lined ball valves

- Range, 1" - 8"

- Body, Graphite fiber-reinforced Vinyl Ester or Epoxy

- Ball, Zirconia Ceramic Standard Port or V-Port for control

- Seats, Zirconia Ceramic or UHMWPE

- Stem, cast-C encapsulated with composite, or solid Hast-C

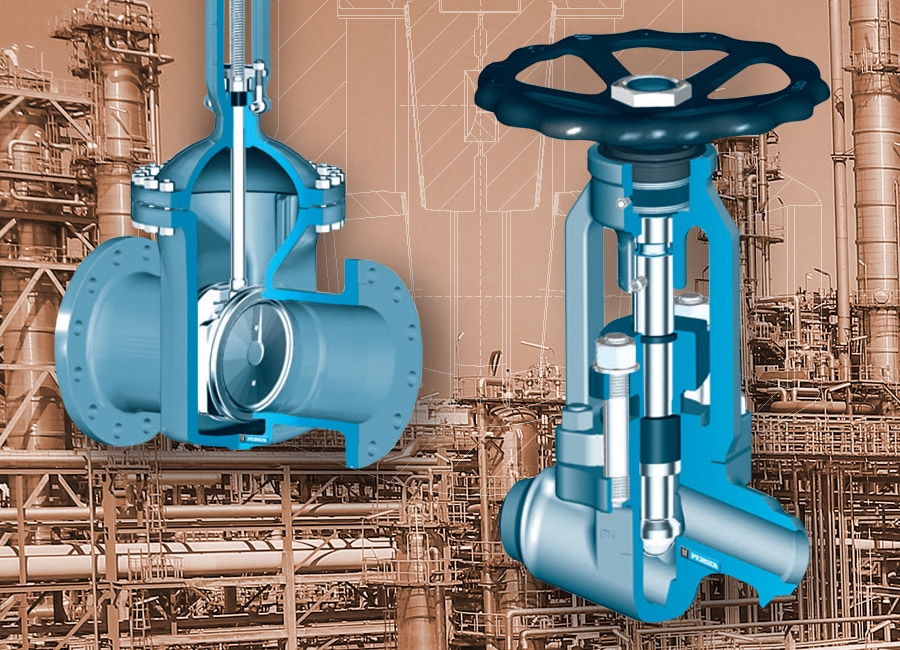

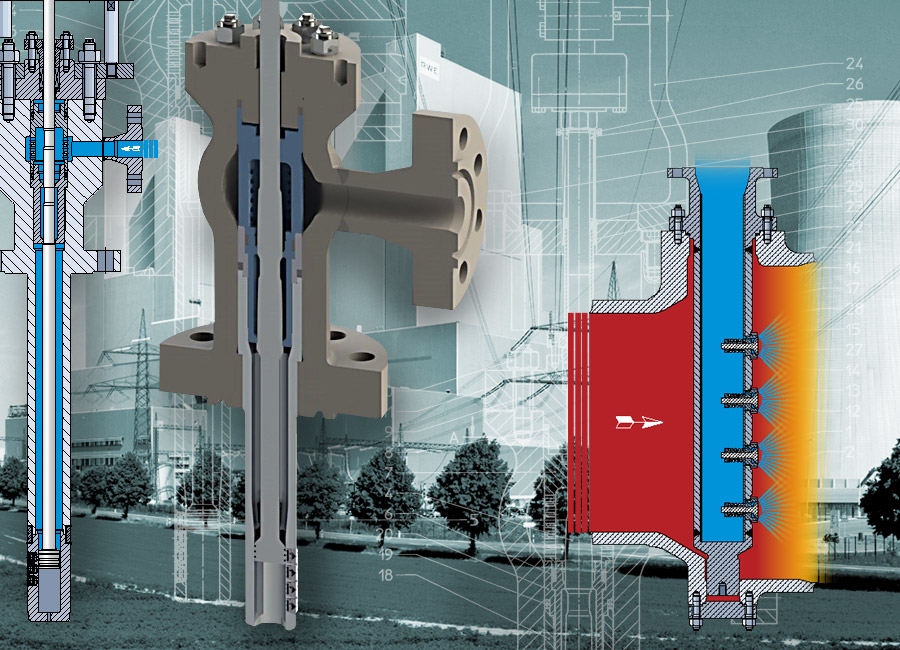

Butterfly valves

- Range, 2"- 42" Wafer and LUG

- Flange drilling, ANSI / DIN

- Types, Full Faced Wafer / Threaded LUG

- Body, Glass fiber-reinforced Vinyl Ester

- Liner, EPDM / Hypalon / UHMWPE

- Disc, EPDM/DI / Hypalon/DC / 316 SS

- Pneumatic / Electro-pneumatic / Manual

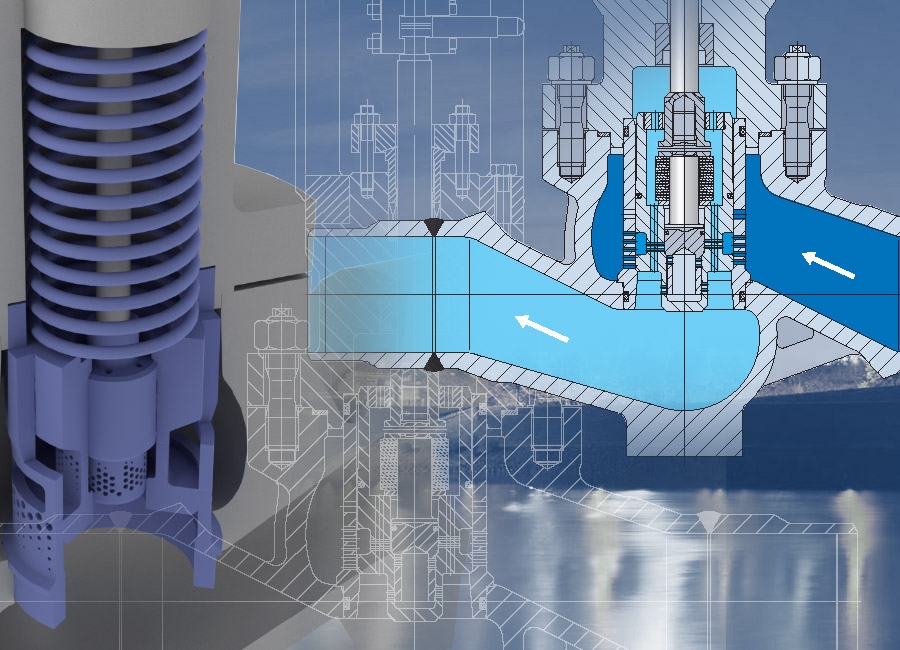

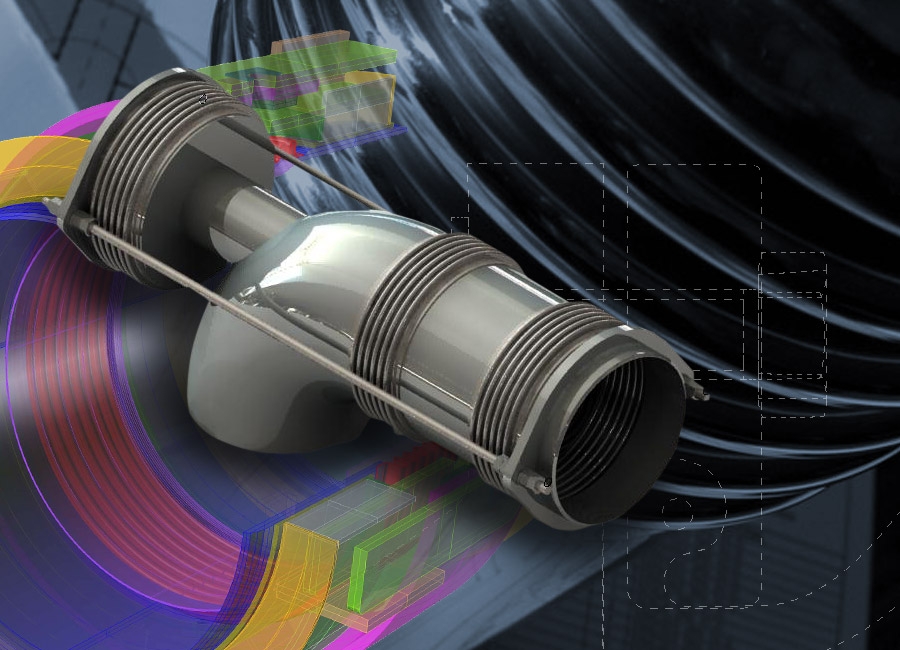

Ball Check Valves

- Range, 1"- 6" Flanged

- Flange drilling, ANSI / DIN

- Construction, One-piece

- Body, 300 Graphite/Vinyl ester, 310 Glass/Vinyl ester, 410 Glass/Polysulfone, 500XP Graphite/Epoxy, 610XP Glass/Epoxy

- Ball, PTFE / Polypropylene

- Seat, FKM Fluorelastomer

Swing Check Valves

- Range, 3" - 12"

- Flange driling, ANSI / DIN

- Construction, One-piece wafer style

- Body, 300 Graphite/Vinyl ester, 310 Glass/Vinyl ester, 500XP Graphite/Epoxy, 610XP Glass/Epoxy

- Flapper, 300 Graphite/Vinyl ester, 310 Glass/Vinyl ester, 500XP Graphite/Epoxy, 610XP Glass/Epoxy

- Seat, FKM Fluorelastomer

Benefits

- Corrosion Resistance

- Light Weight

- Strong and Durable

- Safe and Reliable

Manufacturer

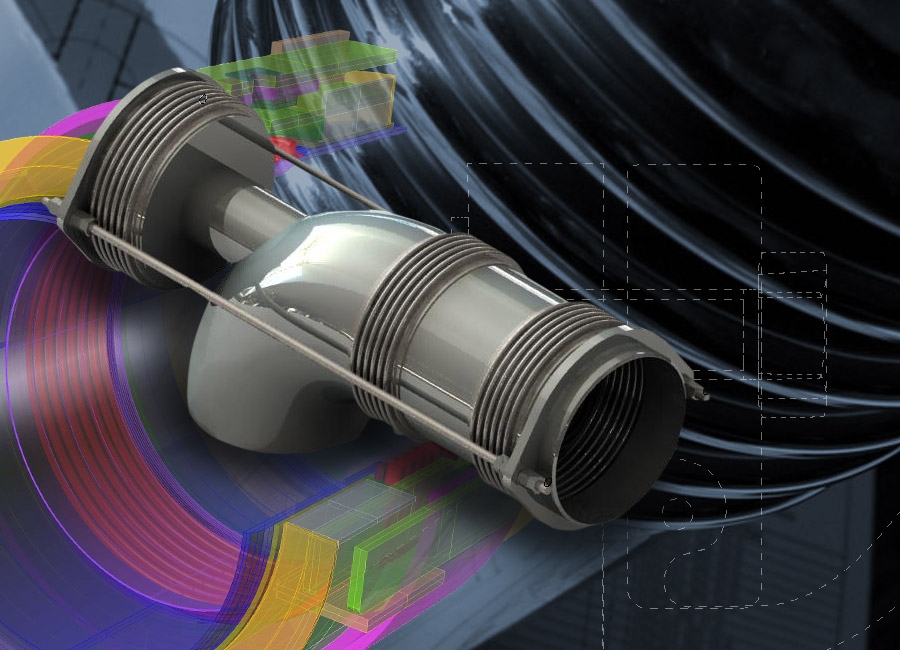

Nil-Cor is a US based manufacturer and worlds-leader of reinforced composite Ball -, Check - and Butterfly valves. Designed acc. ASME Class 150Lbs B16.5 (DIN 2501/PN16) flange rating. Corrosion resistant to a large number of acids, caustics, bleaches, solvents and salts. Good substitutes to expensive and long lead exotic materials. Valves weight approximately 1/3 less then normal valves. Typical applications are cooling - and fire fighting (sea-)water and pure chemicals.

- Graphite - and Glass fiber reinforced Vinyl Ester and Epoxy

- Flanged and Threaded Ball valves

- Ball- & Swing type Check valves

- Wafer/Lug type Butterfly valves with elastomer liners or in full composite

- Ceramic’s for abrasive services