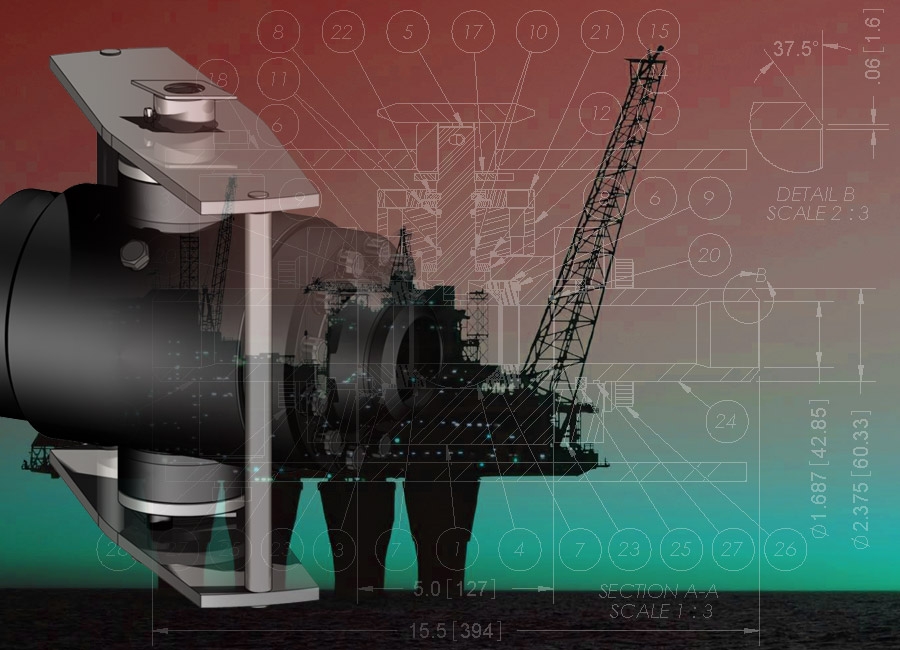

Two shift operation power plants

Power stations that were originally designed for base load applications are now increasingly

being asked to operate on a two shift, stop start regime; this is more commonly known in the

industry as dual shifting. The multiple start/stops that these stations are now experiencing is in

some instances causing an increase of operational issues due to the to the constantly changing

process parameters. For example dual shift stations will experience additional thermal stress in

the headers, drums, high temperature piping, valves plus the auxiliary equipment leading to

additional wear and tear of their systems and component parts. This is due to the more frequent

use of the plant at severe service conditions. The consequences of the change in plant operation

cannot be ignored. If the plant is not operated correctly or more importantly modified properly to

handle these changes the lifetime of the components within the plant will decrease enormously.

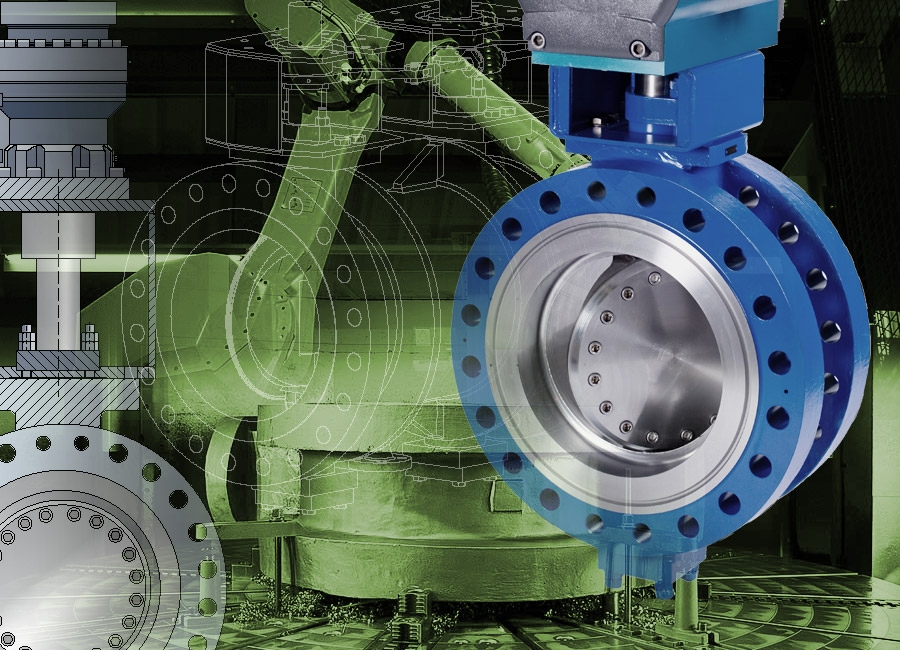

The changing operational requirements of the plant require that the steam coolers, desuperheater

valves, drains, feed water control valves, main steam isolation valves and the turbine

quick closing valves are reviewed. These critical pieces of equipment...

(download de paper in zijn geheel hieronder)