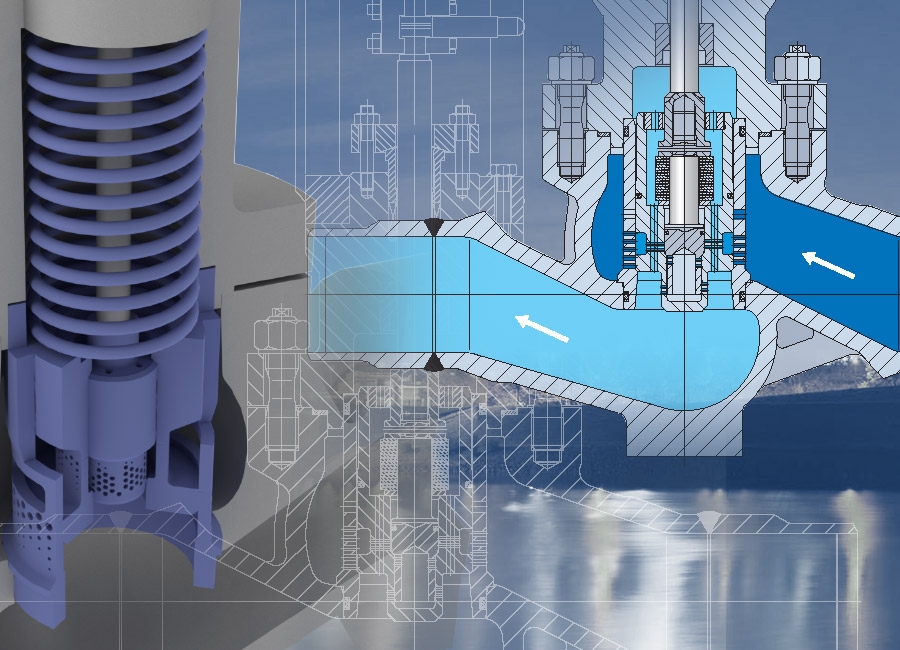

Voedingswater regelkleppen van HORA zijn één van de belangrijkste regelappendages van het water- stoomcircuit. De klep regelt de juiste hoeveelheid voedingswater naar de ketel en het eisenpakket voor een dergelijke appendage is groot. De drukval over de klep moet zo klein mogelijk worden gehouden maar tegelijkertijd moet de klep beschikken over een goede en betrouwbare regelkarakteristiek. De hoofd regelklep is ontworpen voor het maximale waterdebiet bij lage drukverschillen. Een opstartklep, geplaatst in het midden van de hoofdplug, daarentegen wordt ontworpen voor een klein waterdebiet bij hoge drukverschillen. De kleppen worden geëngineerd voor de feitelijke aplicatie. Door de opstartregeling en de hoofdregeling onder te brengen in één klep brengt dit een aanzienlijke kostenbesparing voor de klant met zich mee!

Configuratie

- Hoofddebiet voedingswaterregeling (30-100%)

- Opstartdebiet voedingswaterregeling (0-30%)

- Gecombineerde voedingwater regelklep (0-100%)

Eigenschappen

- Hoogwaardig smeed- of gietstaal

- Z-type, haaks of rechtdoorgaand model

- Las- of flensaansluiting volgens DIN of ANSI

- + klepontlasting / - klepontlasting / pilot plug

- Speciale klepkarakteristiek

- Enkel- of meertrapsconstructie

- Zitting: geklemd

- Plug: gaatjeskooi, gaatjesplug, kaskadeplug

- DIN

- ANSI

- Pneumatisch / elektrisch

Voordelen

- Meertraps anti-cavitatie binnenwerk

- Meertraps binnenwerk processpecifiek ontworpen

- Groot en nauwkeurig regelbereik

- Hoge lekkageklasse

- Onderhoudsvriendelijk

- Geen opstartklep noodzakelijk

Fabrikant

HORA is een Duitse leverancier van hoge druk water- en stoom regelappendages. Het hele programma regelkleppen voor een moderne centrale, zowel kolen gestookt als CCGT (gasturbine met afgassenketels en stoomturbines) centrales alsook stoomnetten kunnen compleet door ons worden geleverd. Samen met het uitstekende R&D team van HORA speuren wij naar verbeteringen voor de kleppen in de water stoom cycle. Flexibele en toegewijd bedrijf, producent van “engineerd” regelkleppen.

- Regelkleppen

- Stoom omvorm ventielen

- Inspuitwater regelkleppen

- Stoomkoelers

- Cooled desuperheaters

- Turbine bypass kleppen (PRDS)

- Turbine snel sluitkleppen

- Automatische recirculatie ventielen

- Kleppen voor ultra super kritische stoomketels